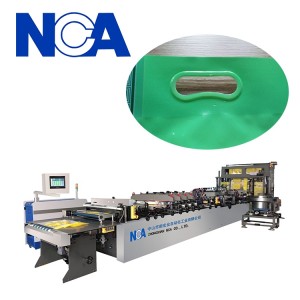

Nca1623b akpaka akpaka akpaka spit

Ojiji

1. A na-eji igwe eji egbutu akụkụ ma weld a plastik spiut na-akpaghị aka.

2.Ọ dị mma maka nnukwu pouches, chrysanthemum msg, mkpụrụ osisi greepu shuga, ịsa mmiri, ịsa mmiri mmiri na ịchọ mma wdg.

3. Dabere na njiri mara ihe ahụ, enwere ike ịhazi akụrụngwa a iji gbochie mmezi ihe mgbe ọpụpụ.

Uru

1, ikike: 40-45PCS / min.

2, Spiut Type: Spiut Spiut, onye ahịa nyere ya. (Φ5mM-φ25mm).

2, akara nke na-eme ihe (4-5 servo), na ụgwọ mmezi.

3, akpaka akpaaka iji belata ọrụ, etiti / akuku sxout.

4, na itinye obere ihe na-ebugharị ma mechaa ngwa ahịa na-ebudata ebu.

Ndepụta nke usoro

Njikwa: PLC (Japan Mitsubishi)

Isi Drive: Servo (Japan Panasonic)

System System: Valum mgbapụta (Germany)

Usoro akara: Usoro (Japan Panasonic)

Pouch na-ahọrọ & ndepụta: cylinder (Japan SMC)

Spout Tinye: Servo (Japan Panasonic)

Nkowa

| Ntinye pouch (l × w w) | Spout Spout: (120-320) × (100-250) MMMAX: 300 × 25mm 320mm 30m 260mm |

| Ibelata akuku | 17º 45º ± 2º 2º |

| Spout ụdị | Spout spiut, onye ahịa nyere ya. (Φ5mM-φ25mm) |

| Arụ ọrụ arụpụta | 40-45 iberibe / min (obere pouch) 35-40 iberibe / min (pouch buru ibu) ndetu |

| Ike | Ac380v, 50hz, 11KW, 3P |

| Ikuku ikuku | 0.7MPA, 250nl / min |

| Akụkụ (l × W × H) | 5700 × 3000m 1900mm |

| Mmiri jụrụ oyi | 6l / min |

| Aro | 2000Kg |